3D printing is an exciting, cost-effective option for DIY hobbyists and home manufacturing pros. With 3D printers, you can create any object you like with relative ease. Instead of relying on complicated traditional manufacturing processes, today’s fabrication is often fast and simple. It’s as easy as making (or finding) a computer software design and then clicking “print.”

In this article, we’ll explore how 3D printers work, the limitations and potential of the technology, and more.

Creating a digital 3D model

Designing three-dimensional objects takes practice, but many software options on the market will teach you quickly without much complication. For instance, Tinkercad is a computer-aided design program made for children, and the easy-to-use interface makes it a great choice for beginners.

With Tinkercad, you can select from premade 3D objects, or combine them to build something new. Or you can start from scratch for an original design.

Because Tinkercad is a free browser-based app, you can use it from any computer. Just create an account, and the program will even save your 3D print files for future use. Once you finish your first 3D modeling project, you can export it as an STL or OBJ file for 3D printing.

Printing layer by layer with slicing

Think of your 3D model as a LEGO structure. In order to build anything, you have to start at the bottom and lay down bricks layer by layer. 3D printing works in a similar way. The 3D printer interprets your STL file or OBJ file as a series of horizontal slices. The slices are almost like a very thin layer of Lego bricks.

Some 3D design software prepares files into slices for your 3D printer to print automatically. Others may require you to slice your 3D model with separate slicer software. If you’re using a 3D build platform that doesn’t automatically slice your model, don’t worry. Programs like Slic3r, Repetier, and Simplify3D are great ways to slice your file before you print.

How does a 3D printer actually print?

There are several different types of 3D printers on the market. Some print with layers of different materials like thermoplastic pellets or metal powder. Most home or desktop 3D printers are filament-based. These use spools of durable materials like PLA or ABS plastics for printing.

A traditional inkjet printer lays ink on paper with a print head. In a similar way, a 3D printer uses an extruder head to heat and extrude the raw material filament onto a platform or stage. The extruder heats the filament and moves along two axes. As it moves, it applies the heated filament to form each printed slice.

Layer by layer, the extruder prints the filament into your design. Soon the printed object begins to take shape.

The 3D printer will often add support structures to aid the additive manufacturing process. These structures, typically referred to as “legs,” help support the weight of the object as it prints, and they’re removed after the job is done.

Limitations in 3D printing technology

The 3D printing process can be finicky. Complex digital files or those with interlocking or moving parts present a challenge. Often, those more challenging printed parts must be designed as separate files. You can print each component separately, then assemble them in a later step.

Most 3D printers will occasionally experience extrusion temperature errors, or movement of the build platform. If your 3D print is complex or will take more than just a few hours, take care to track its progress. With tracking, it’s easier to catch problems early.

Speed, quality, and post-processing

Desktop 3D printers are generally slow. That makes them less well-suited for mass production or fabricating parts that demand tight tolerances. However, they’re efficient tools during the design process and work well for rapid prototyping. You can create new iterations of an idea from home, with little waiting between prototypes.

When your 3D model comes off the printer, you’ll still need to remove the supports and sand it for a more finished look. Many at-home 3D designers also paint their products.

3D printing services

Some 3D designers like to use at-home printers for prototyping and improving a design. Once they’re happy with the results, they’ll send their 3D object files to a 3D printing service for a high-quality finished product.

For printing simple 3D objects like a small toy or an accessory for your GoPro, at-home desktop 3D printers are sufficient. But for complex printing like automotive accessories or metal objects, using a 3D printing service is ideal.

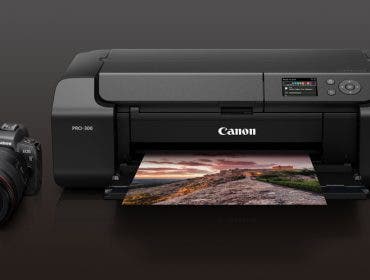

Read More: 9 Best Printers For Photographers